Engineering Services

Petrocon Engineers and Consultants offer a comprehensive suite of engineering services designed to meet the diverse needs of industrial projects. Our expertise spans multiple disciplines, ensuring integrated solutions that enhance project efficiency, safety, and compliance with global standards.

Back to Plant Engineering Services

Basic Engineering

Basic Engineering is the intermediate design phase in oil & gas projects used to define technology, equipment sizing, process configuration, cost estimates, and project scope. It provides enough detail for accurate CAPEX estimates and for preparing tenders for EPC (Engineering–Procurement–Construction).

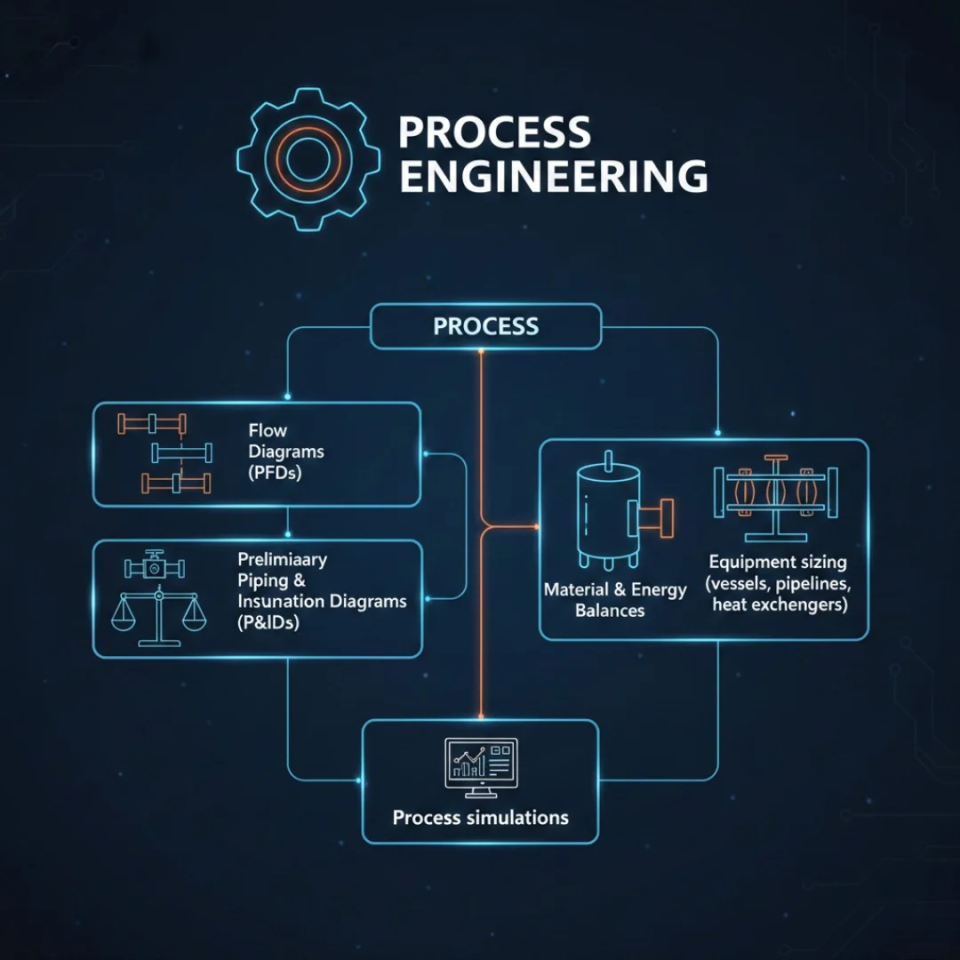

Process Engineering

Process engineering activities include the preparation of Process Flow Diagrams (PFDs) and preliminary Piping & Instrumentation Diagrams (P&IDs), development of material and energy balances, equipment sizing for vessels, pipelines, and heat exchangers, and execution of process simulations to analyze operating conditions, validate design assumptions, and support efficient and safe system performance.

Mechanical Engineering

Preparation of mechanical data sheets, development of package specifications for systems such as compressor and pump packages, and creation of preliminary equipment layouts to support coordinated design, space optimization, and efficient integration within the overall plant arrangement.

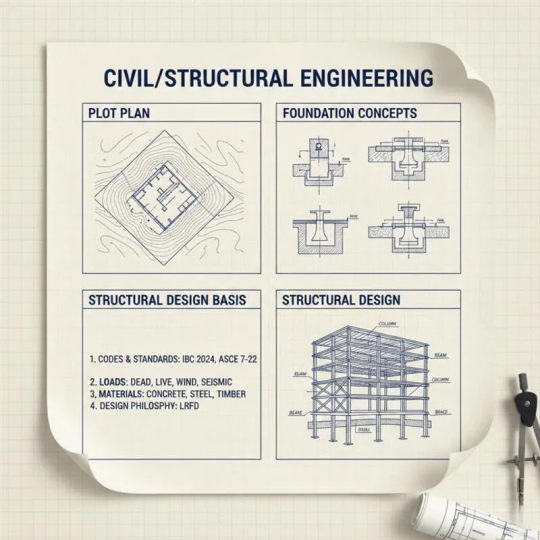

Civil & Structural Engineering

Development of the plot plan, establishment of foundation concepts, and preparation of the structural design basis to define layout arrangements, loading criteria, and design standards for safe, stable, and constructible plant structures.

Electrical & Instrumentation Engineering

Preparation of single-line diagrams, development of power load lists, compilation of the instrument list, and definition of the control system philosophy to establish electrical distribution, load requirements, instrumentation scope, and overall control and automation strategy.

Safety & Environment

Conducting preliminary Hazard and Operability (HAZOP) studies, performing risk assessments, carrying out flare and relief system analyses, and addressing environmental impact basics to identify potential hazards, evaluate risks, ensure system protection, and support compliance with safety and environmental requirements.

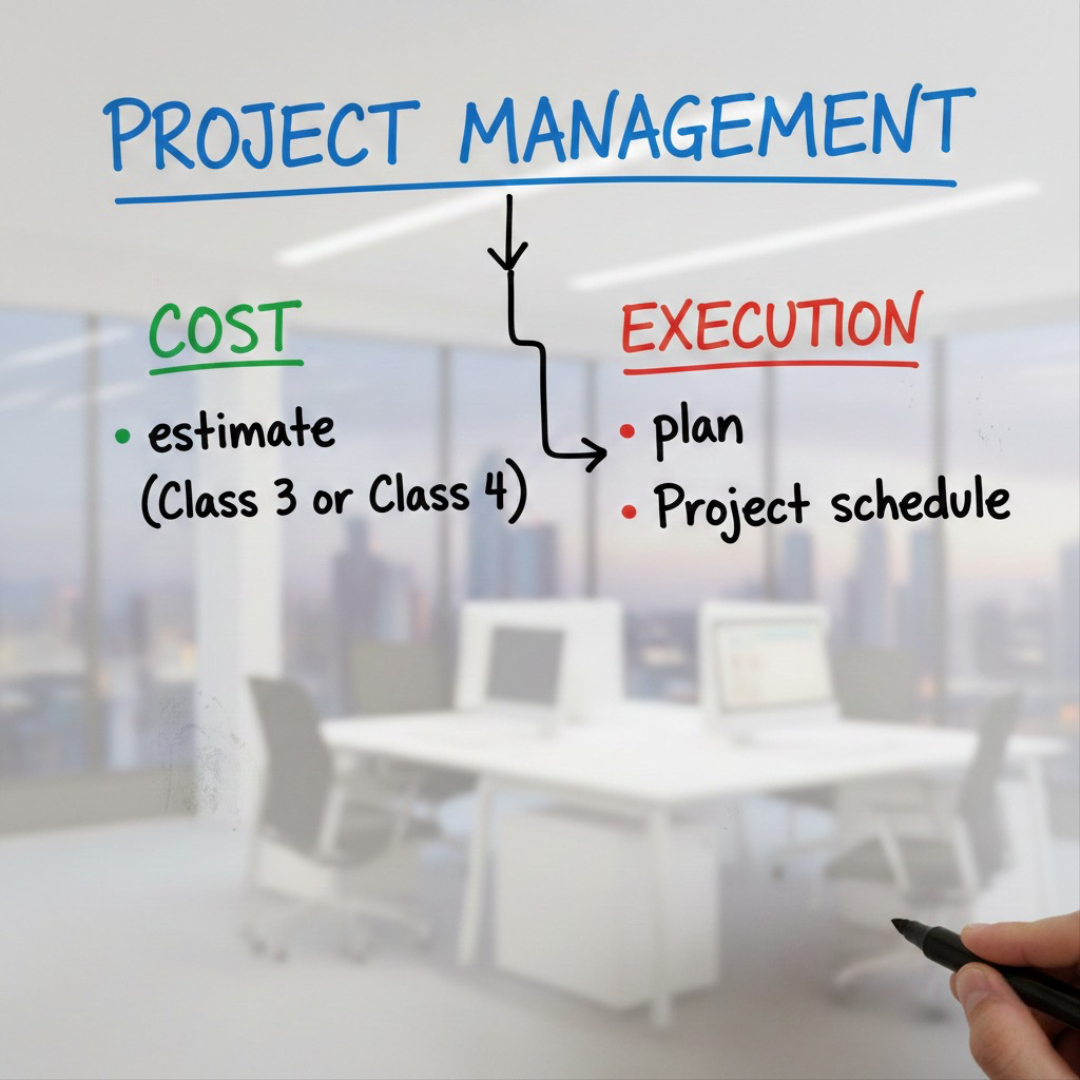

Project Management

Preparation of Class 3 or Class 4 cost estimates, development of the execution plan, and establishment of the project schedule to define project scope, budgeting accuracy, implementation strategy, and key milestones for effective project delivery.

Oil & Gas

Experience across a wide range of energy and process facilities, including onshore oil production facilities such as Central Processing Facilities (CPF) and Gas Oil Separation Plants (GOSP), offshore platforms, gas processing plants, LNG plants, refineries, pipeline networks, and storage terminals.

Ready to Elevate Your Project? Contact Us Today!

Don't leave your projects to chance. Contact our lead consultant today to discuss your project requirements.