Instrumentation & Control Engineering Services

Specializes in Field and Analytical Instrumentation, Field-to-DCS/PLC Integration, and ICSS implementation for Accurate, Reliable control with Safety Compliance

Back to Plant Engineering Services

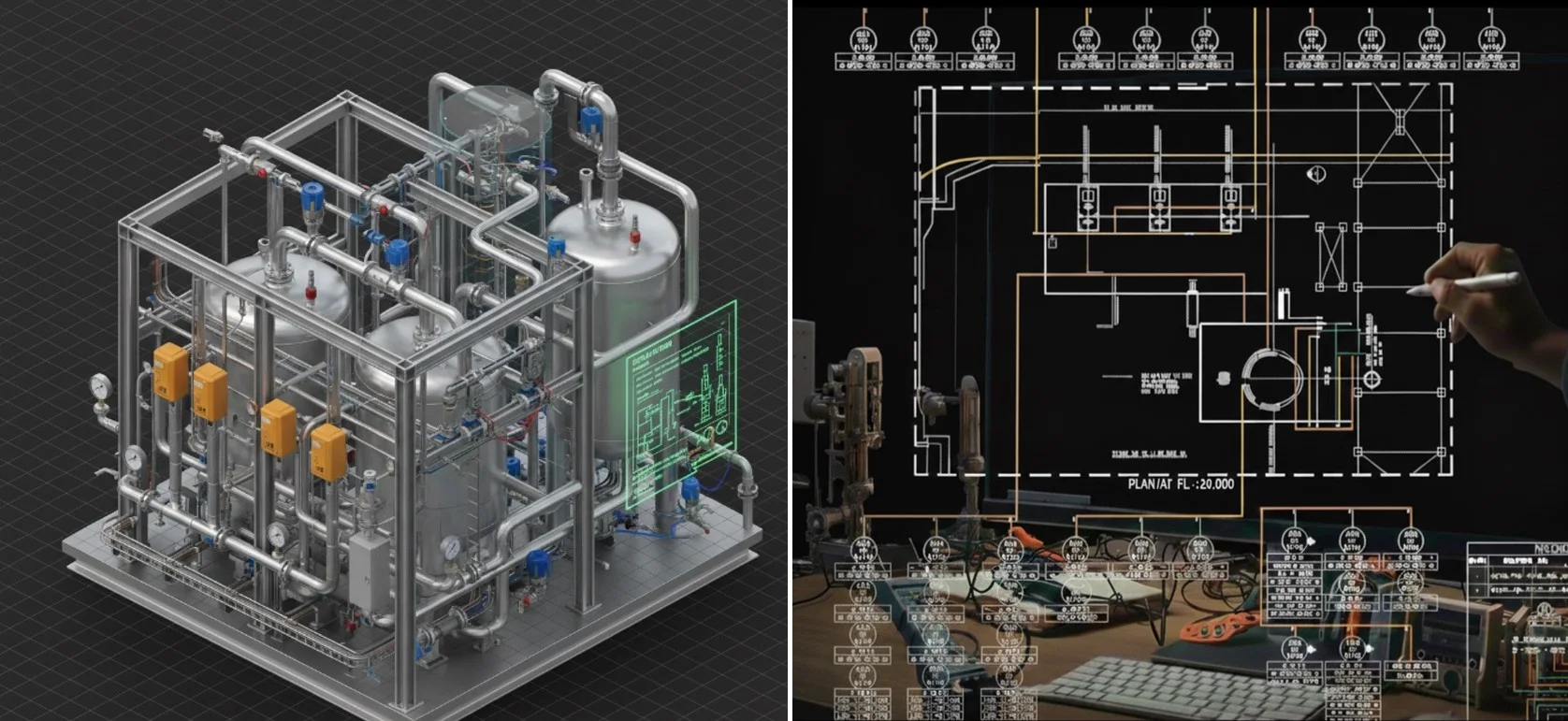

2D/3D Engineering Design

Developing detailed 2D drawings and 3D models for Instrumentation and Control Systems, ensuring accurate integration with Process and Plant Layouts using Advanced CAD, SP3D, E3D, MicroStation, and SmartSketch.

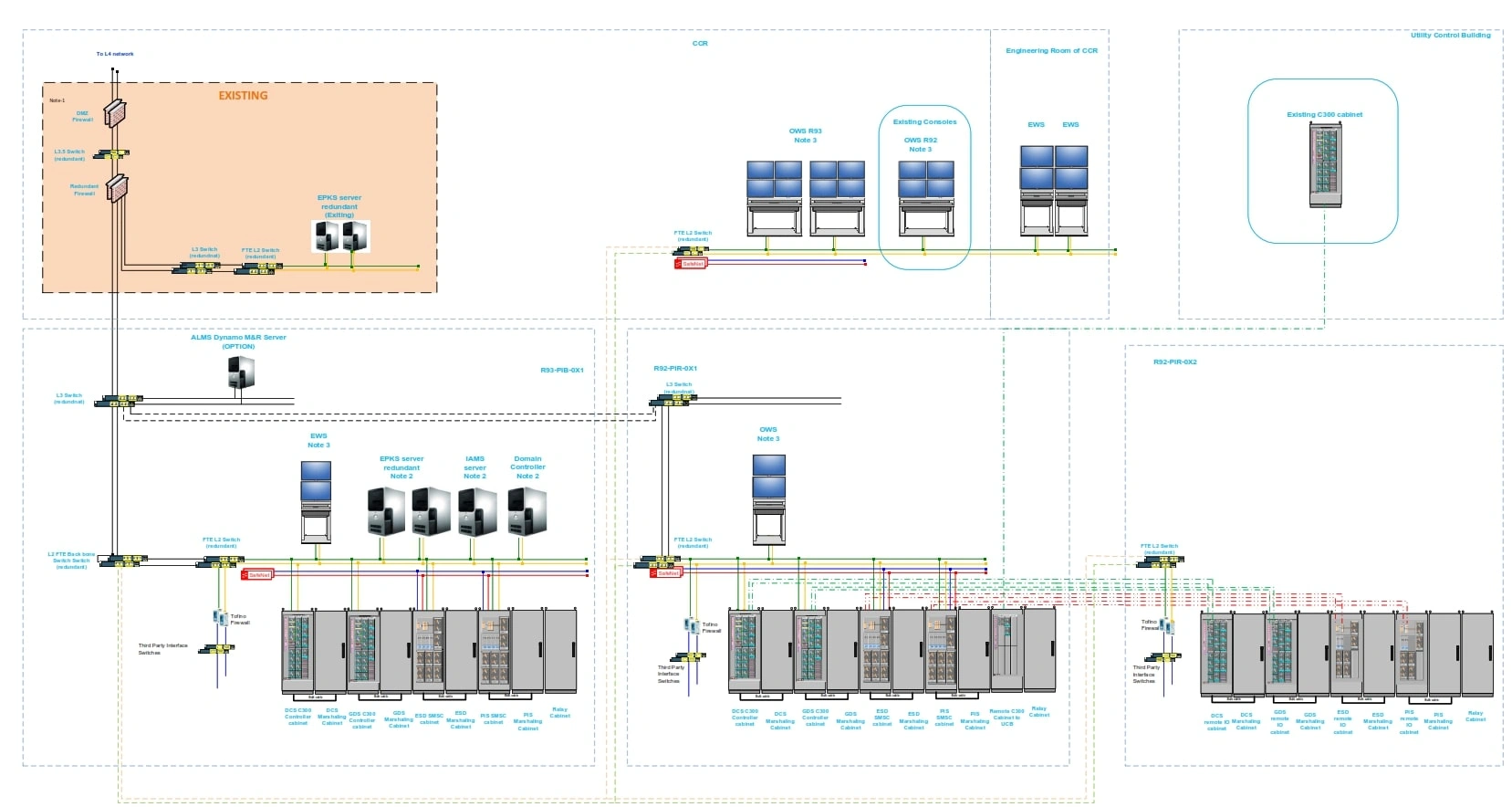

Instrument Schematic block diagram & System Architecture

Design and development of complete instrument grouping based on location, segregation philosophy and control system architecture to define the functional layer and physical layout of instrumentation. Ensures all instruments, controllers, and interfaces are properly organized for optimal performance.

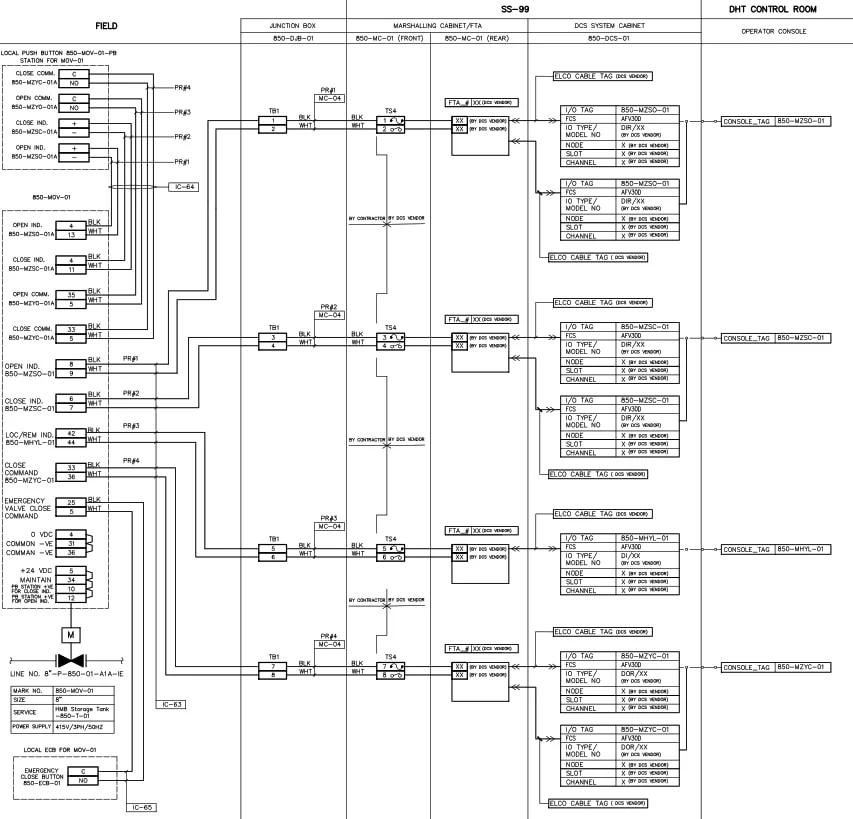

Instrument Loop Diagram

Preparation of Detailed wiring diagrams for field and control systems, ensuring accurate connections from Field to Junction Box to IO cards. Diagrams cover Signal, Power, and Instrument grounding details to facilitate installation and testing. Enables easy troubleshooting and maintenance for reliable system performance.

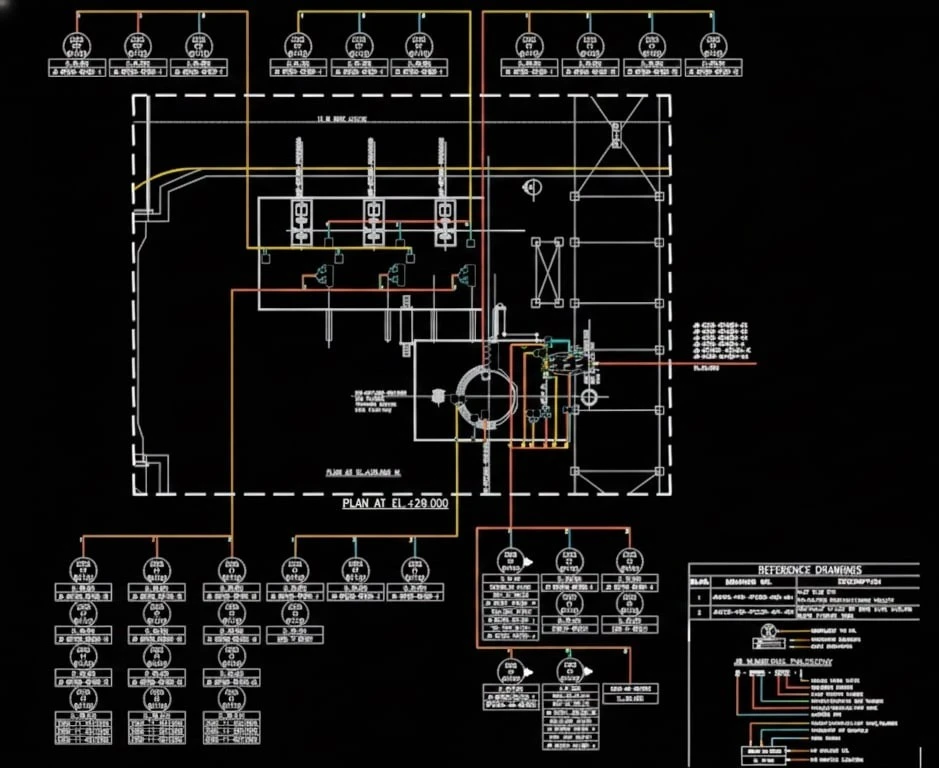

Instrument Location Layout & Cable Routing Layout

Creation of precise layouts showing Instrument Locations, Cable Trays, and Conduit Routing across plant areas. Ensures safe, accessible, and coordinated installation while avoiding clashes with Piping, Mechanical, Electrical, and Structural systems. Enhances constructability and long-term maintenance efficiency.

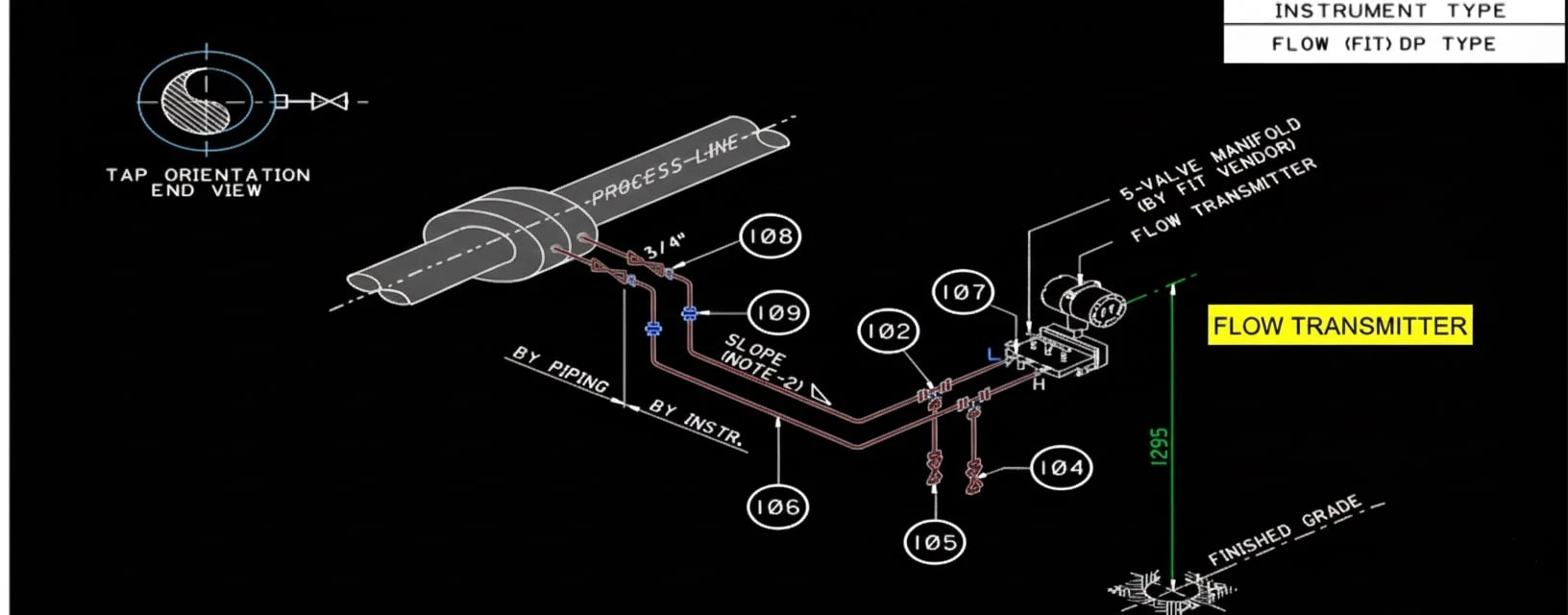

Instrument Hook-up & Instrument Installation Drawing

Preparation of detailed instrument hookup and installation drawings for field devices, panels, and junction boxes. Provides input to bulk material procurement and step-by-step guidance for correct assembly, mounting, and connection. Facilitates accurate field installation and reduces rework during commissioning.

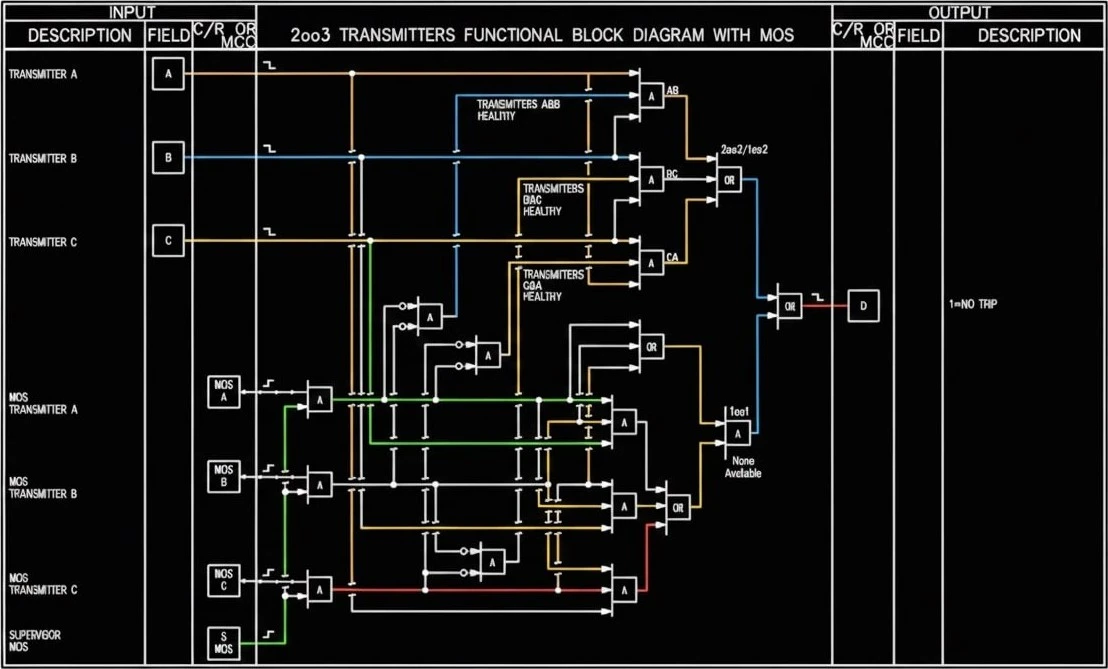

Cause & Effect and Logic Diagram

Design of Cause & Effect and Logic Diagrams for Control and Safety Instrumented Systems, illustrating initiators, Final element Interlocks, Permissive, Voting Logic, Alarms, Maintenance overrides and Functional sequences. Ensures proper control strategies and safe operational behaviour. Supports Commissioning, Troubleshooting, and Compliance with Industry Standards.

SP3D (SmartPlant 3D)

Petrocon delivers advanced 3D modelling for Instrumentation Layouts, Field Devices, Junction Boxes, Panel Racks, Cable-trays using SP3D. This enables precise positioning of Transmitters, Analysers, Panels, and Impulse Tubing within realistic plant environments. Built-in Clash Detection and access validation ensure safe and efficient installation planning.

AVEVA E3D

We utilize AVEVA E3D to deliver high-precision 3D modelling of Instruments, Analysers, Transmitters, Junction Box & Cable-management systems, achieved through discipline-wise coordination. Advanced visualization enables efficient Design reviews and Informed Engineering decision-making. Through E3D, Petrocon Designers provides safe, efficient, and installation-focused instrumentation and control solutions.